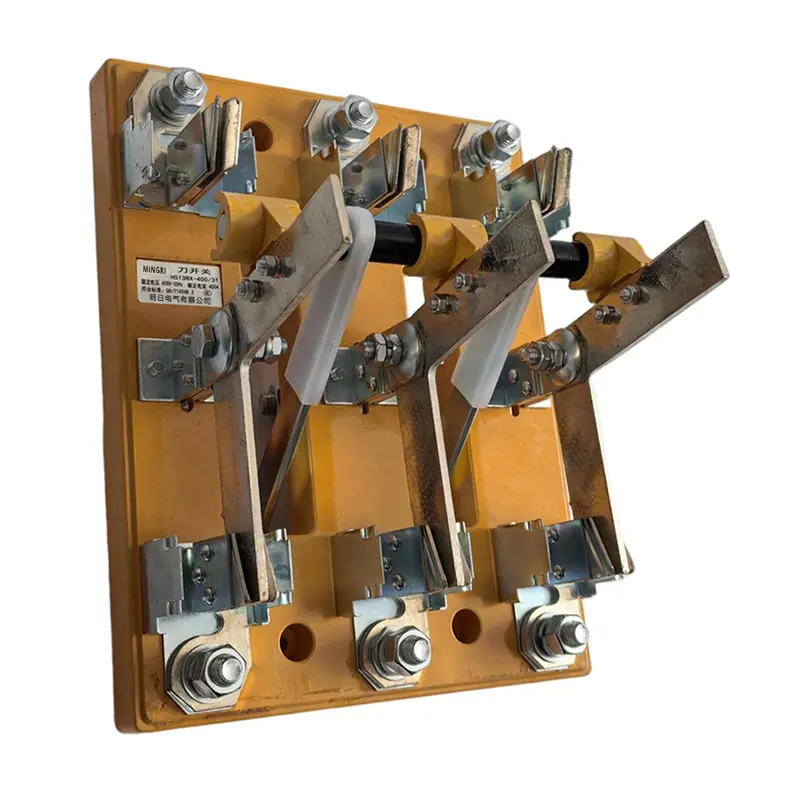

Top Manufacturer of SC(B)11 Transformers | Reliable Wholesale Suppliers

Mingri Electric Co., Ltd. offers high-quality SC(B)11 Transformers engineered for efficiency and durability in diverse applications. Our transformers leverage advanced technology to perform reliably, ensuring they meet the needs of various business operations. We prioritize exceptional customer service, guiding clients from initial inquiries to product delivery, ensuring satisfaction at every stage. Choosing our SC(B)11 Transformer guarantees you receive a product that boosts performance and reliability, crucial for success in your projects. Partner with us to optimize your electrical solutions.

Step-by-Step Guide To SC(B)11 Transformer Factory Service

In today’s fast-paced industrial landscape, ensuring reliable power distribution is critical for operational success. The SC(B)11 transformer plays a vital role in achieving this goal, and understanding its factory service process can enhance your procurement strategy. This guide aims to provide a concise overview of the step-by-step service procedures to ensure your transformers are maintained at peak performance.

The first step in the factory service process involves comprehensive inspections and testing. During this phase, specialized equipment evaluates the mechanical and electrical integrity of each unit to identify any potential issues. Following inspection, a detailed maintenance protocol is initiated, which may include the replacement of worn components, recalibration of settings, and rigorous testing of electrical parameters. Additionally, every transformer undergoes a thorough cleaning to remove any debris or contaminants, ensuring optimal functionality.

Finally, after successfully completing the necessary service steps, each transformer is subjected to end-of-line testing. This crucial process guarantees that the unit meets all regulatory standards and performs efficiently under load conditions. Once certified, the transformers are prepared for dispatch, ensuring they arrive at your facility ready for installation and immediate use. By understanding this factory service process, global buyers can make informed decisions, secure reliable products, and ultimately safeguard their circuits effectively.

Step-by-Step Guide To SC(B)11 Transformer Factory Service

| Step Number | Service Description | Required Tools | Safety Precautions | Estimated Time |

|---|---|---|---|---|

| 1 | Shutdown the transformer and ensure all power sources are disconnected. | Insulation resistance tester, voltage meter | Use personal protective equipment (PPE) | 30 minutes |

| 2 | Inspect and clean all external components. | Brushes, cleaning agents | Avoid exposure to cleaning chemicals | 1 hour |

| 3 | Check oil levels and conditions; replace if necessary. | Oil sample kit, oil pump | Handle oil with care | 1.5 hours |

| 4 | Test insulation resistance and integrity. | Insulation tester | Follow electrical safety protocols | 45 minutes |

| 5 | Perform functional tests and report any anomalies. | Functional testing equipment | Ensure all testing is carried out in safe conditions | 2 hours |

Why China’s SC(B)11 Transformer Manufacturer Industry Leaders

C

Charlotte White

Very high quality, indeed! The support staff was super knowledgeable and their service was prompt and helpful.

09

July

2025

A

Avery Wright

Remarkable quality! The after-sales service staff was very efficient and well-prepared to help.

22

August

2025

D

Daniel Hernandez

High-quality materials used in this product. The service representatives were professional and responded promptly.

20

July

2025

S

Sandra Wright

Quality is on point, and the service team was very professional. They made my experience enjoyable.

22

July

2025

A

Anthony Baker

I’m very pleased with this purchase. The service team demonstrated exceptional professionalism throughout.

30

June

2025

R

Ruth Campbell

Beautifully crafted product. The customer service representatives were courteous and incredibly informed.

13

July

2025

Claire

Claire Mr.Fu

Mr.Fu

Claire

Claire