10kV Ring Main Unit (RMU) Operation Manual

This article provides a concise operational overview for certified electrical personnel handling 10kV Ring Main Units (RMUs). Always prioritize safety and adhere to local regulations and the manufacturer-specific manual before any operation.

- Safety Precautions

Qualified Personnel Only: Operations must be performed by trained, authorized personnel with high-voltage certification.

Personal Protective Equipment (PPE): Wear insulated gloves, arc-flash suits, and safety goggles. Use voltage detectors and earthing equipment.

Isolation & Lockout/Tagout: Ensure the RMU is de-energized, isolated from all power sources, and grounded before maintenance. Use lockout/tagout procedures to prevent accidental re-energization.

Environmental Checks: Avoid operation in humid, corrosive, or explosive environments.

- Key Operational Steps

- Switching ON (Energizing)

Verify that all load switches/breakers are in OFF position.

Ensure earthing switches are OPEN (disengaged) and mechanically/electrically indicated.

Close the incoming power source switch first, followed by the outgoing feeder switches.

Confirm voltage stability via indicators or meters.

- Switching OFF (De-energizing)

Open all outgoing feeder switches to disconnect loads.

Open the incoming power source switch.

Verify de-energization using a voltage detector.

Engage earthing switches for safe maintenance.

- Interlocks & Safety Features

Mechanical/electrical interlocks prevent:

Closing earthing switches under load.

Closing load switches when earthing is engaged.

Never bypass interlocks—they are critical for preventing fatal errors.

- Emergency Handling

Abnormal Conditions: If arcing, smoke, or unusual noises occur, immediately de-energize the RMU and evacuate the area.

Fault Reporting: Document and report faults to supervisors and manufacturers for analysis.

- Maintenance Guidelines

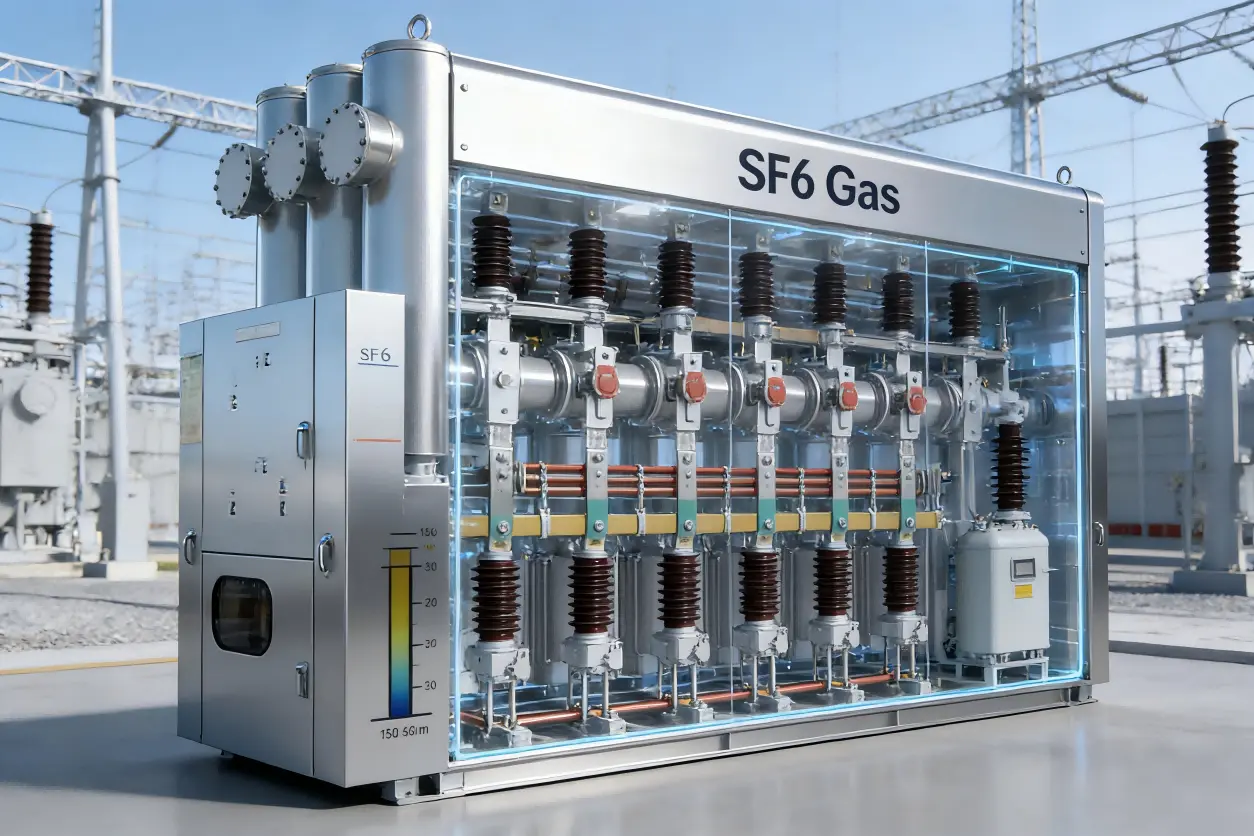

Routine Checks: Inspect for insulation damage, corrosion, loose connections, and SF6 gas leaks (if applicable).

Scheduled Maintenance: Clean insulation surfaces, tighten electrical joints, and lubricate mechanical components annually.

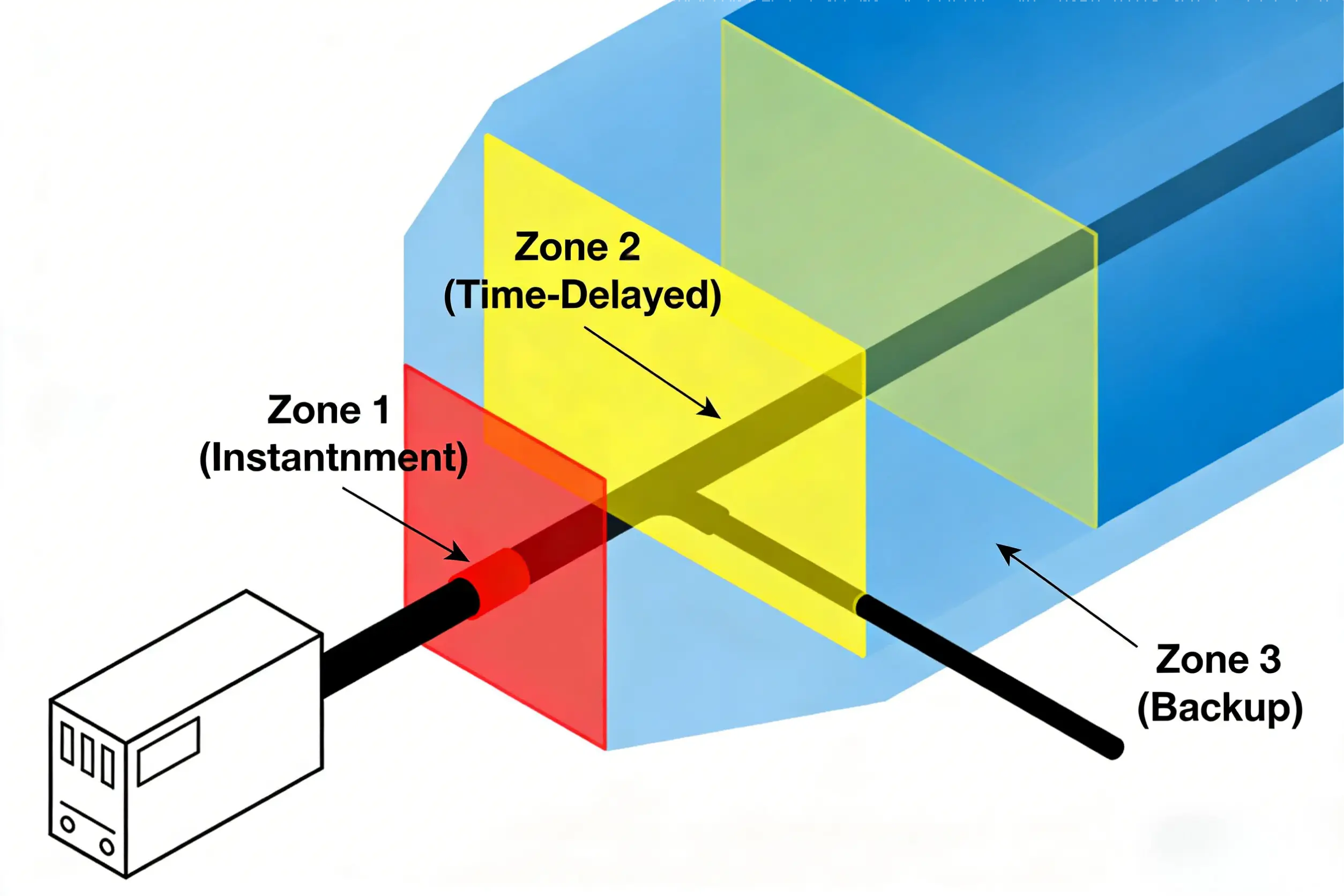

Testing: Validate protection relays, metering, and interlock functionality periodically.

- Warning

Do not operate under load unless the RMU is rated for load-breaking (e.g., using load-break switches).

Never disable safety interlocks—this risks equipment damage and severe injury.

This summary is generic and must not replace the manufacturer’s official manual. Always consult device-specific documentation and local safety standards before operations.

Stay Safe—Operate Responsibly!

Claire

Claire Mr.Fu

Mr.Fu

Claire

Claire