Ensuring Reliability: A Behind-the-Scenes Look at Mingri Electric's Air-Insulated Switchgear

● How Our Rigorous Gas Filling and Testing Process Guarantees Long-Term Performance ?

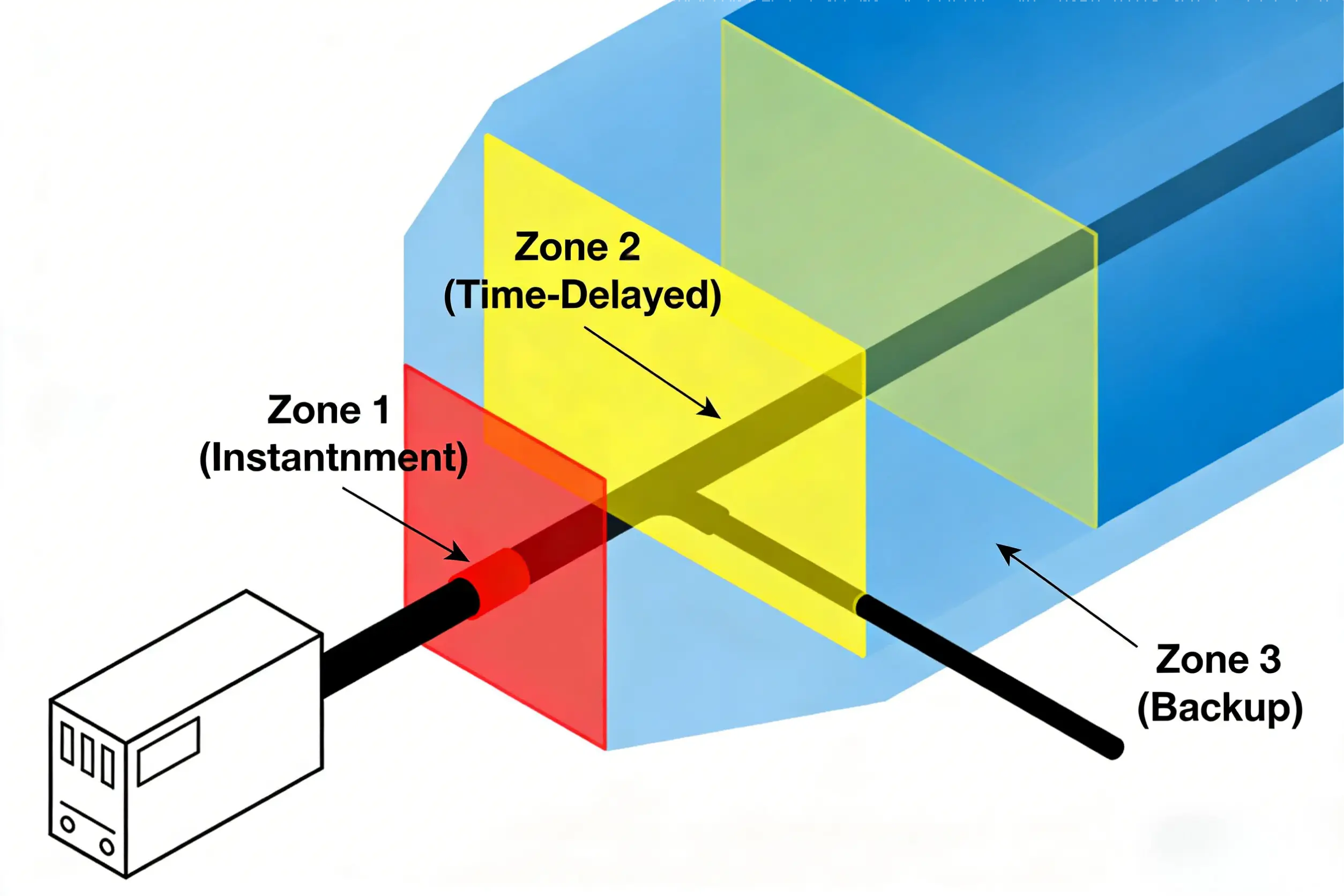

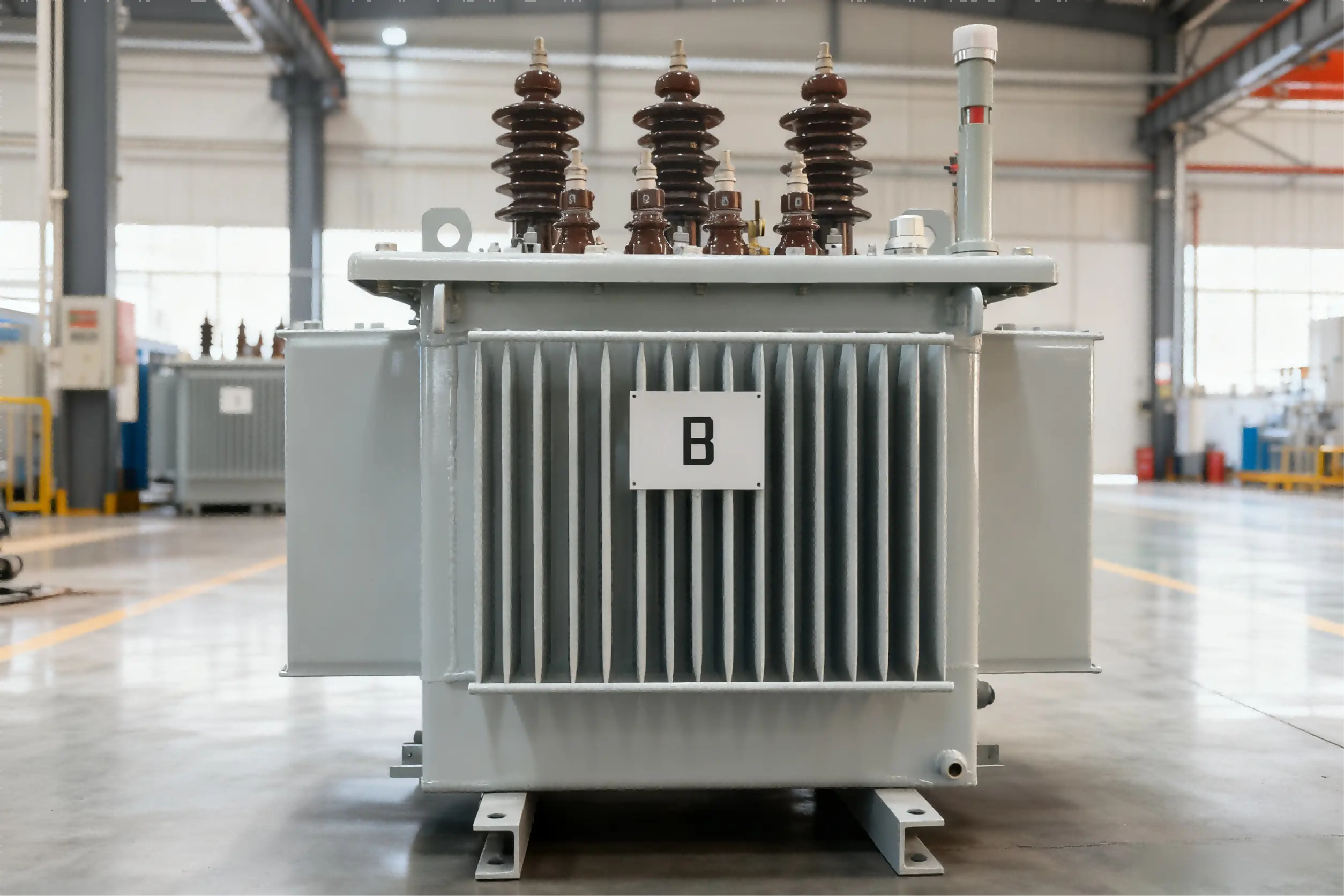

As the backbone of many modern power distribution networks, Air-Insulated Switchgear (AIS) plays a critical role in controlling, protecting, and isolating electrical equipment in medium-voltage applications. At Mingri Electric, we don't just manufacture these essential components; we engineer them for unparalleled reliability and longevity. This article takes you behind the scenes to explore one of the most critical phases in our production workshop: the precise gas filling and exhaustive testing that set our AIS apart.

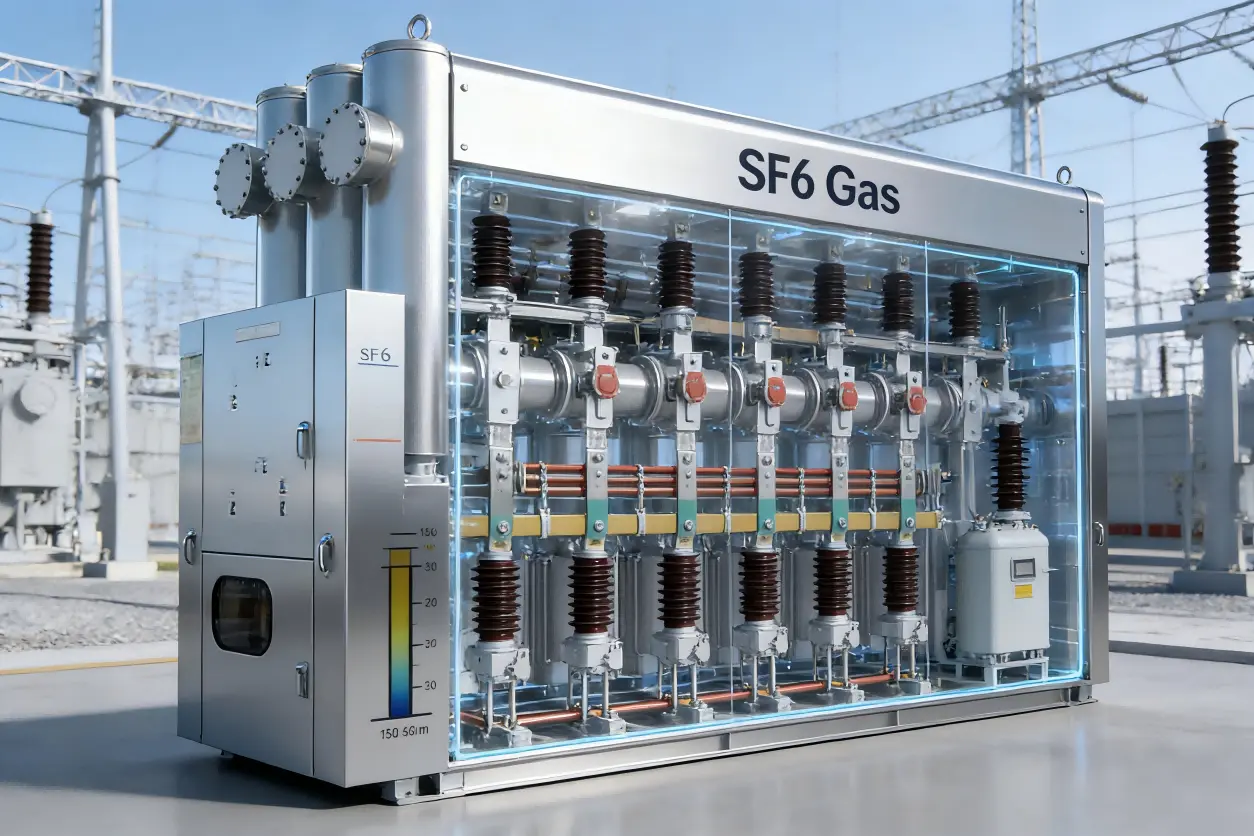

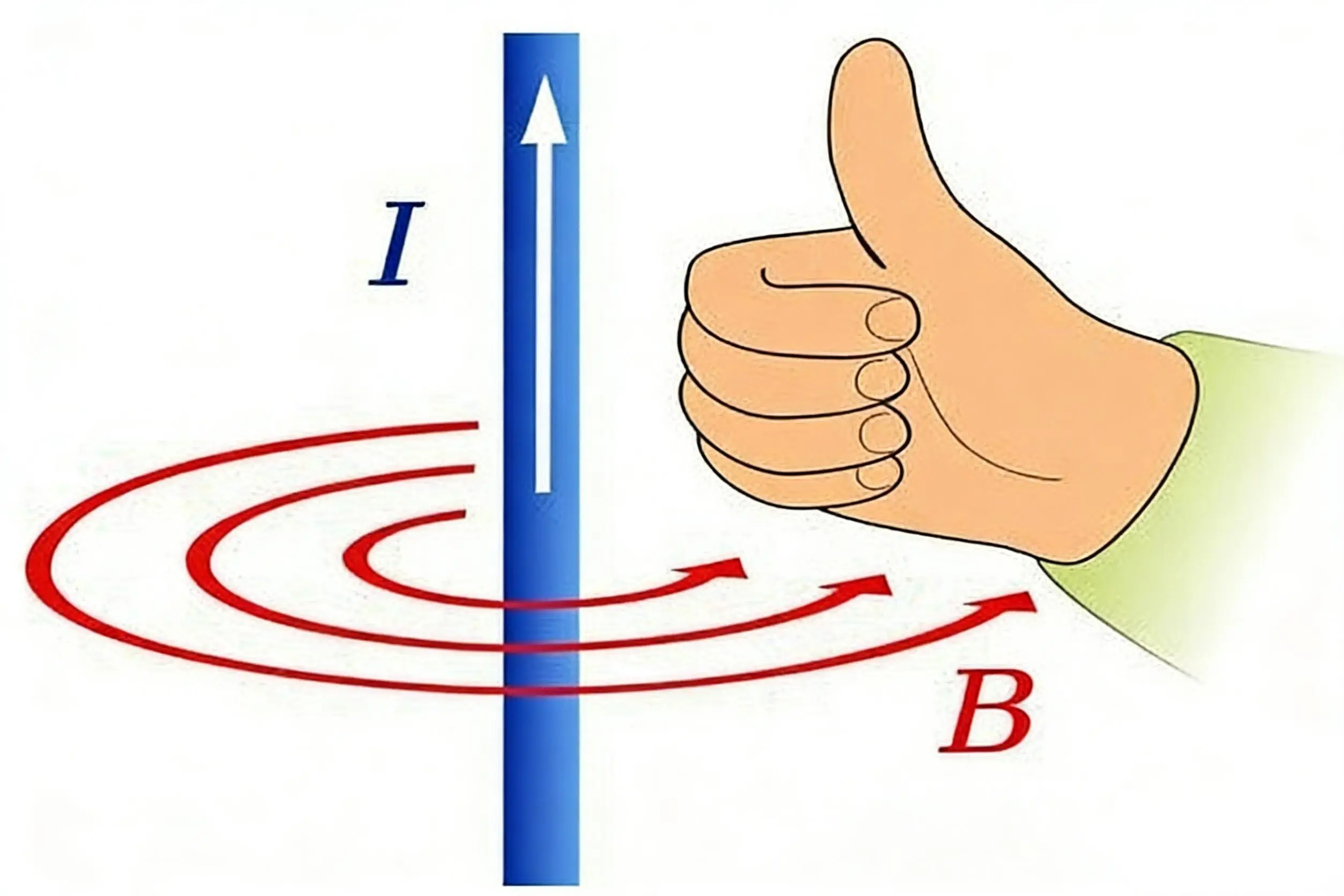

Although the switchgear is "air-insulated," specific compartments, particularly those housing the circuit breaker, require a specific type of gas—most commonly SF6 or advanced eco-friendly alternatives—for superior arc-quenching and insulation properties. The process of filling this gas is far from trivial; it is a cornerstone of the unit's long-term reliability.

At our workshop, this is a meticulous operation. After ensuring the unit is completely sealed, our technicians use specialized, calibrated equipment to evacuate all moisture and air from the chamber, creating a deep vacuum. This step is crucial to prevent any impurity from compromising the dielectric strength of the gas. Only then is the high-purity gas carefully filled to a precisely calculated density and pressure, strictly following the manufacturer's specifications. This precision ensures consistent interrupting performance and prevents internal faults throughout the equipment's operational life.

★ The Mingri Electric Promise: Quality You Can Trust

For us, these processes are not just items on a checklist. They are a reflection of our commitment to every client. By investing such care and precision into the manufacturing of our Air-Insulated Switchgear, we deliver products that minimize lifecycle costs, reduce unexpected outages, and provide peace of mind. We empower our partners to build safer, more resilient electrical infrastructure.

★ Ready to Experience the Difference?

If you are looking for reliable, high-performance switchgear backed by transparent and rigorous manufacturing standards, look no further than Mingri Electric.

Contact us today to discuss your project requirements or Visit our website to learn more about our full product range and capabilities.

Claire

Claire Mr.Fu

Mr.Fu

Claire

Claire