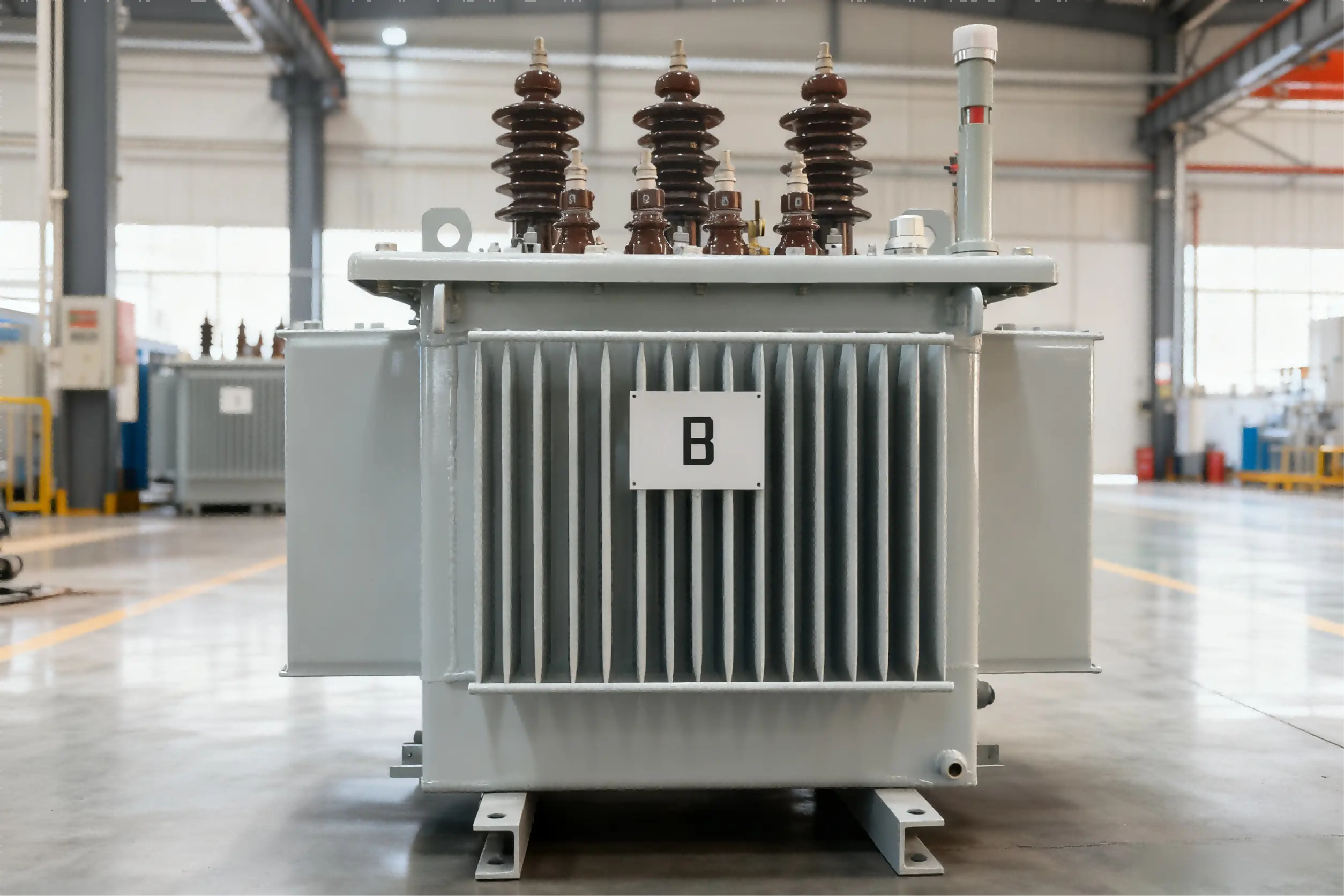

A Look Inside Mingri Electric: The Precision Journey of a High-Voltage Ring Main Unit

At Mingri Electric, we firmly believe that Precision products stem from precise control over every manufacturing detail. Today, we sincerely invite you to join us on this "virtual tour" to gain an in-depth understanding of how a high-performance High-Voltage Ring Main Unit transforms from raw materials into a key asset ensuring grid safety and reliability.

Caption: Step into the core manufacturing area of Mingri Electric, where all our high-quality electrical products are born.

Part 1:

Precision Manufacturing, Starting from the First Process

Caption: Our engineer conducts a rigorous incoming inspection of custom-made, high-precision sheet metal components.

The manufacturing of an RMU begins with demanding the utmost from fundamental components. Every sheet metal enclosure used by Mingri Electric is custom-made by premium suppliers strictly according to our blueprints. Before entering the assembly line, these custom parts undergo our stringent dimensional and material inspections to ensure their precision and quality fully meet the standards. Subsequently, through precise positioning and bending processes, these sturdy plates are formed into structures of specified dimensions, laying a solid foundation for the subsequent flawless assembly.

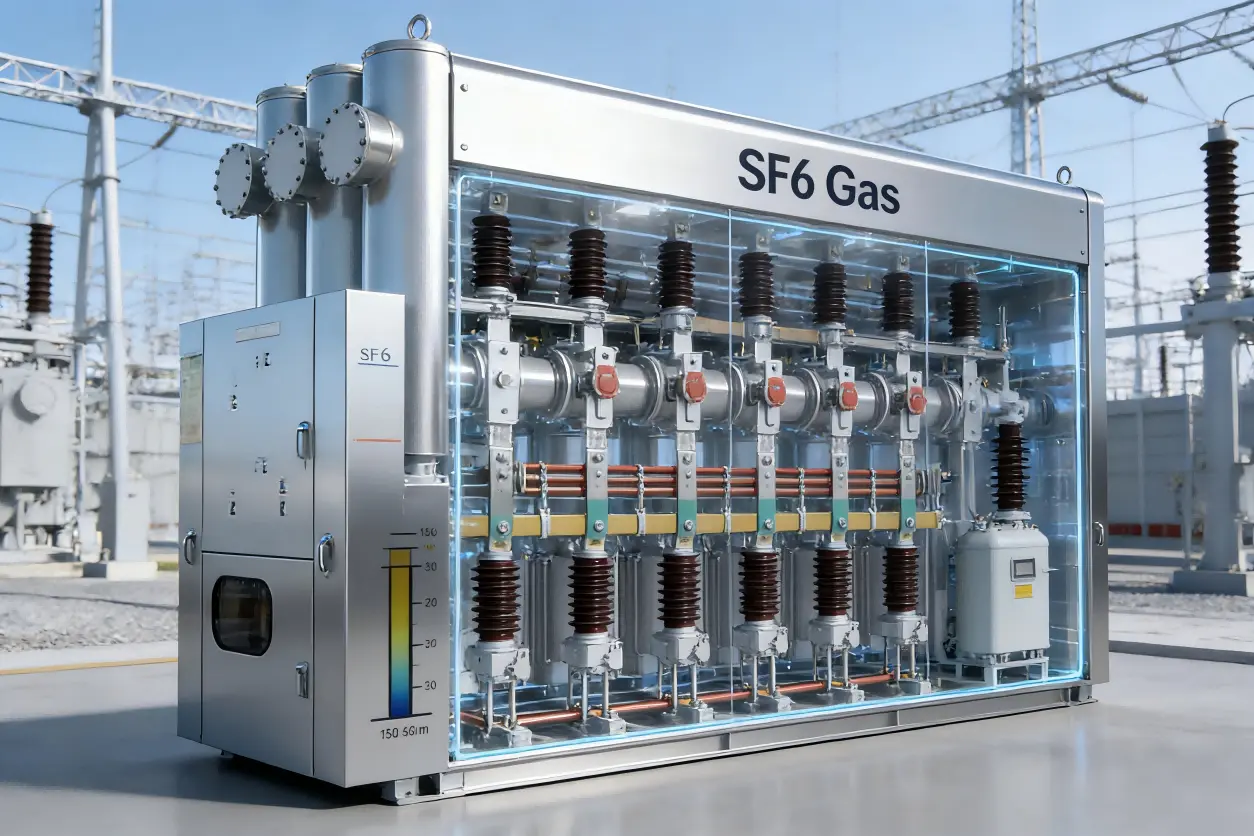

Part 2:

Rigorous Assembly, Where Quality is Integrated into Every Step

Caption: Experienced engineers at Mingri Electric perform primary circuit assembly strictly in accordance with work instructions.

The assembly line is where the product "comes to life." At Mingri Electric, our team of experienced engineers follows standard operating procedures to install core components such as circuit breakers, disconnectors, transformers, and protection devices. We emphasize a "zero-defect" assembly philosophy, utilizing professional tools (e.g., torque wrenches) to ensure the reliability and safety of every connection point.

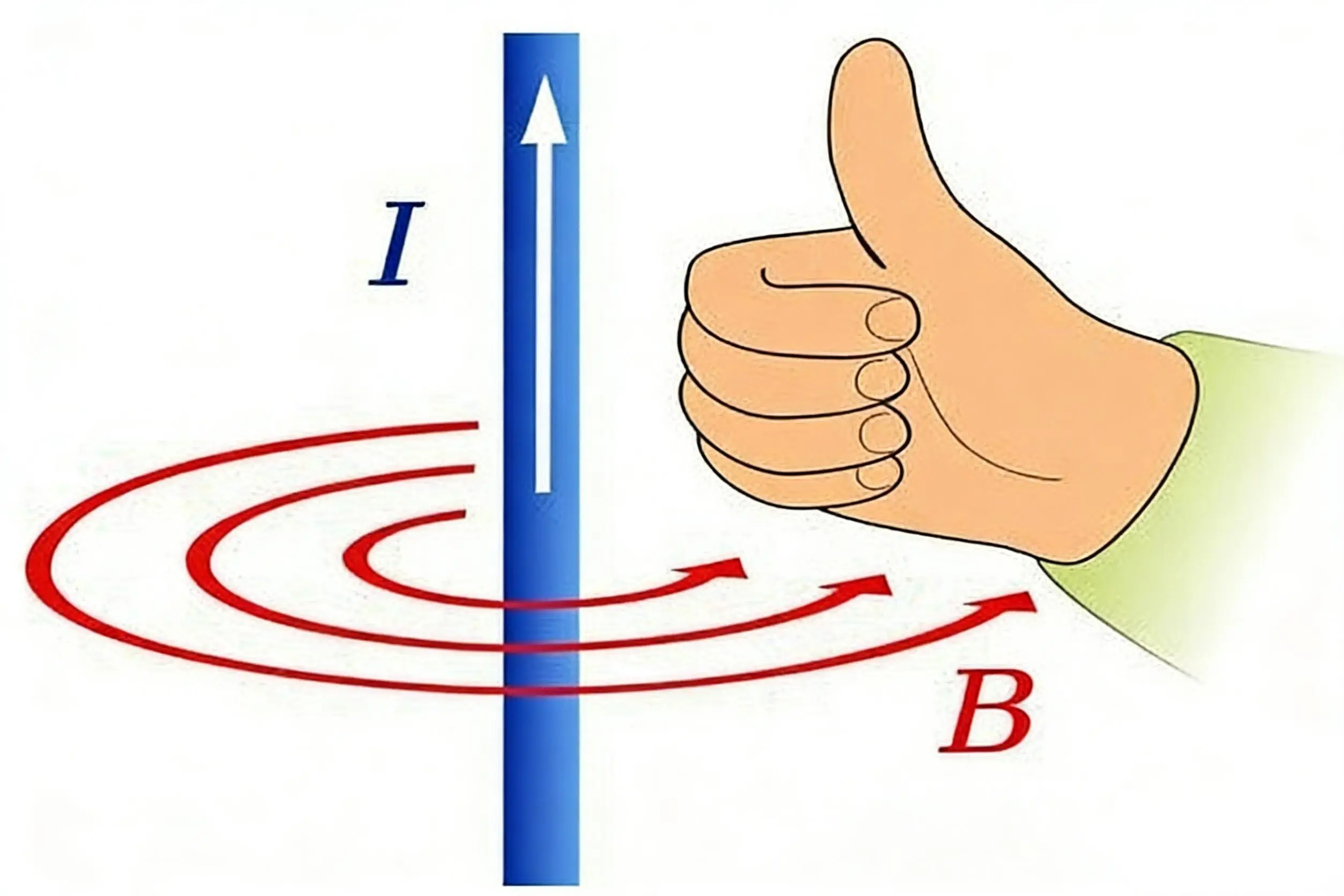

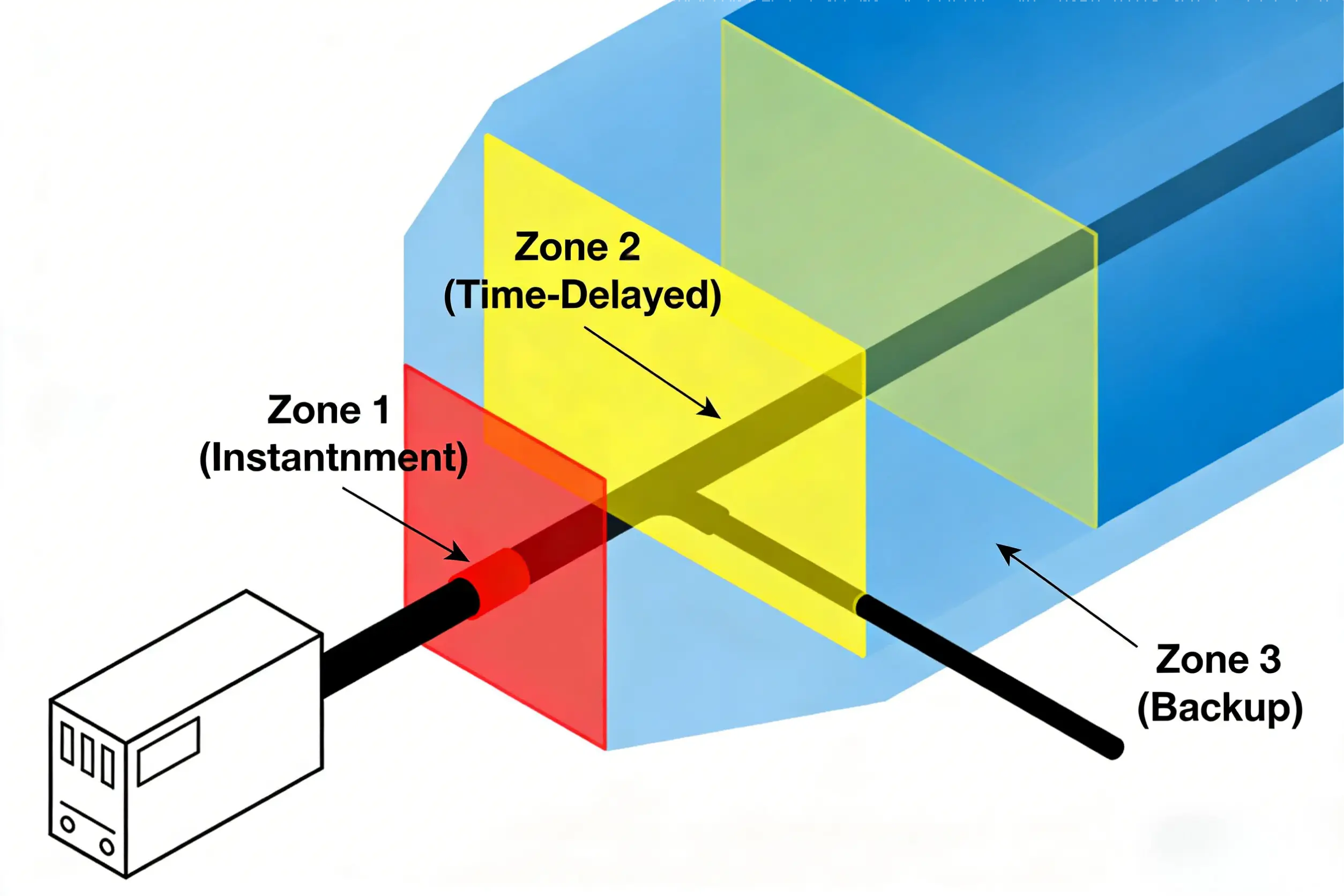

Part 3:

Stringent Testing, Safeguarding for Safe Operation

Caption: At Mingri Electric, every unit leaving our factory must pass a full set of type tests, including power-frequency withstand voltage tests.

Quality is our non-negotiable bottom line. Every assembled RMU at Mingri Electric must undergo a full set of rigorous tests in our testing center. These include, but are not limited to: Power-frequency withstand voltage test, Partial discharge test, Mechanical operation test, and Protection function verification. We simulate various harsh operating conditions to ensure the safety and performance of the product are fully validated before delivery to you.

Part 4:

System Certification: Our ISO 9001 Quality Commitment

Caption: Mingri Electric strictly implements the ISO 9001:2015 Quality Management System standard, delivering reliable products and services to every customer.

Every aspect we have showcased operates within the framework of the ISO 9001:2015 Quality Management System. This internationally recognized standard permeates the entire process at Mingri Electric, from raw material procurement and manufacturing to final inspection. It is not just a certificate on the wall but an integral part of our corporate culture, ensuring our product quality is stable, traceable, and subject to continuous improvement, ultimately fulfilling every commitment we make to our customers.

Conclusion:

We hope this brief tour has given you a sense of Mingri Electric's dedication to craftsmanship and respect for quality. What we offer is not just a product, but the entire trustworthy manufacturing system and quality commitment behind it. Please feel free to contact us for more information. We look forward to cooperating with you.

About Us:

Mingri Electric Co., Ltd. is a leading provider of high-quality electrical components and solutions, specializing in switchgear,circuit breakers,switches, etc. We are dedicated to delivering innovative products that meet the evolving needs of the global power industry.

Claire

Claire Mr.Fu

Mr.Fu

Claire

Claire