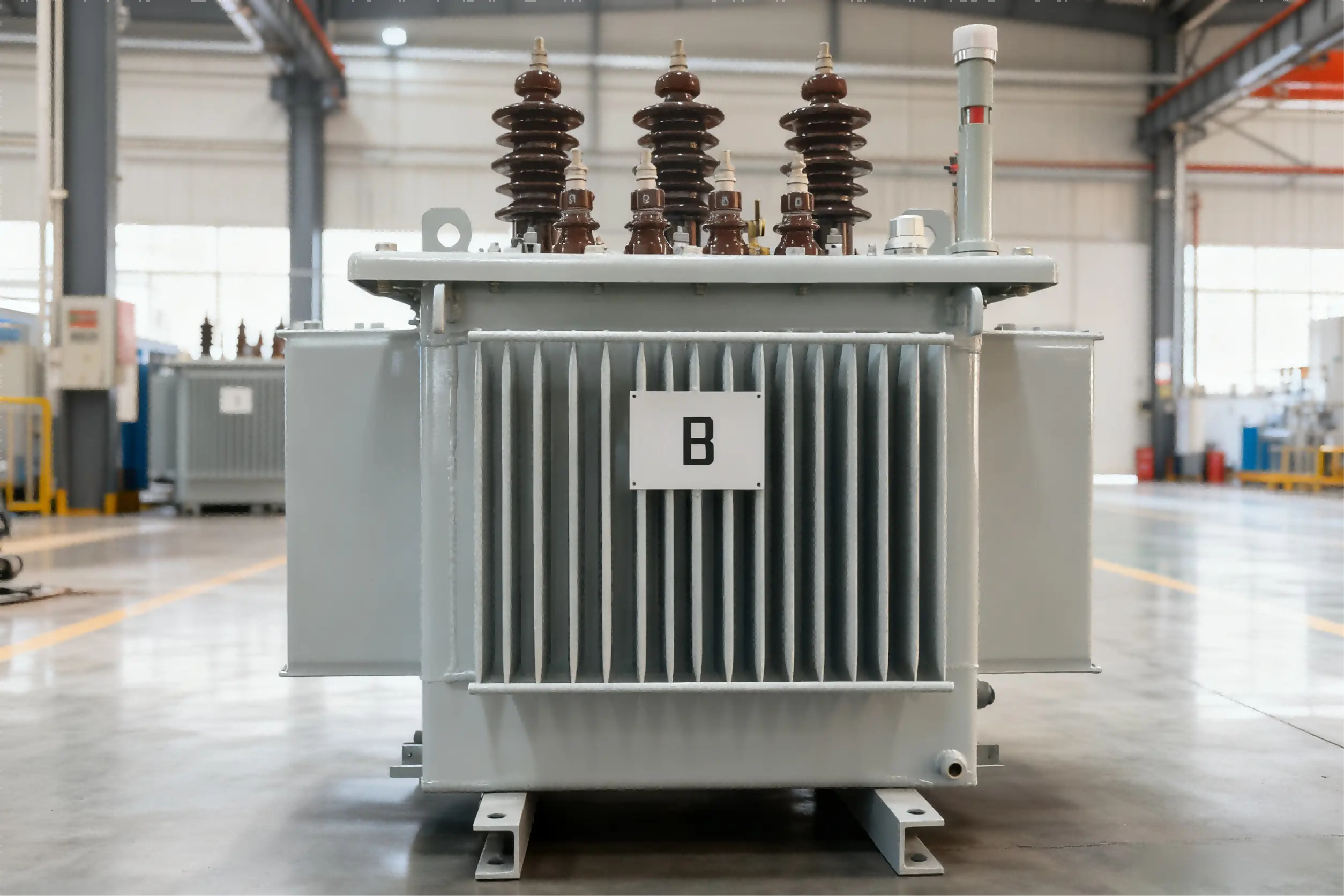

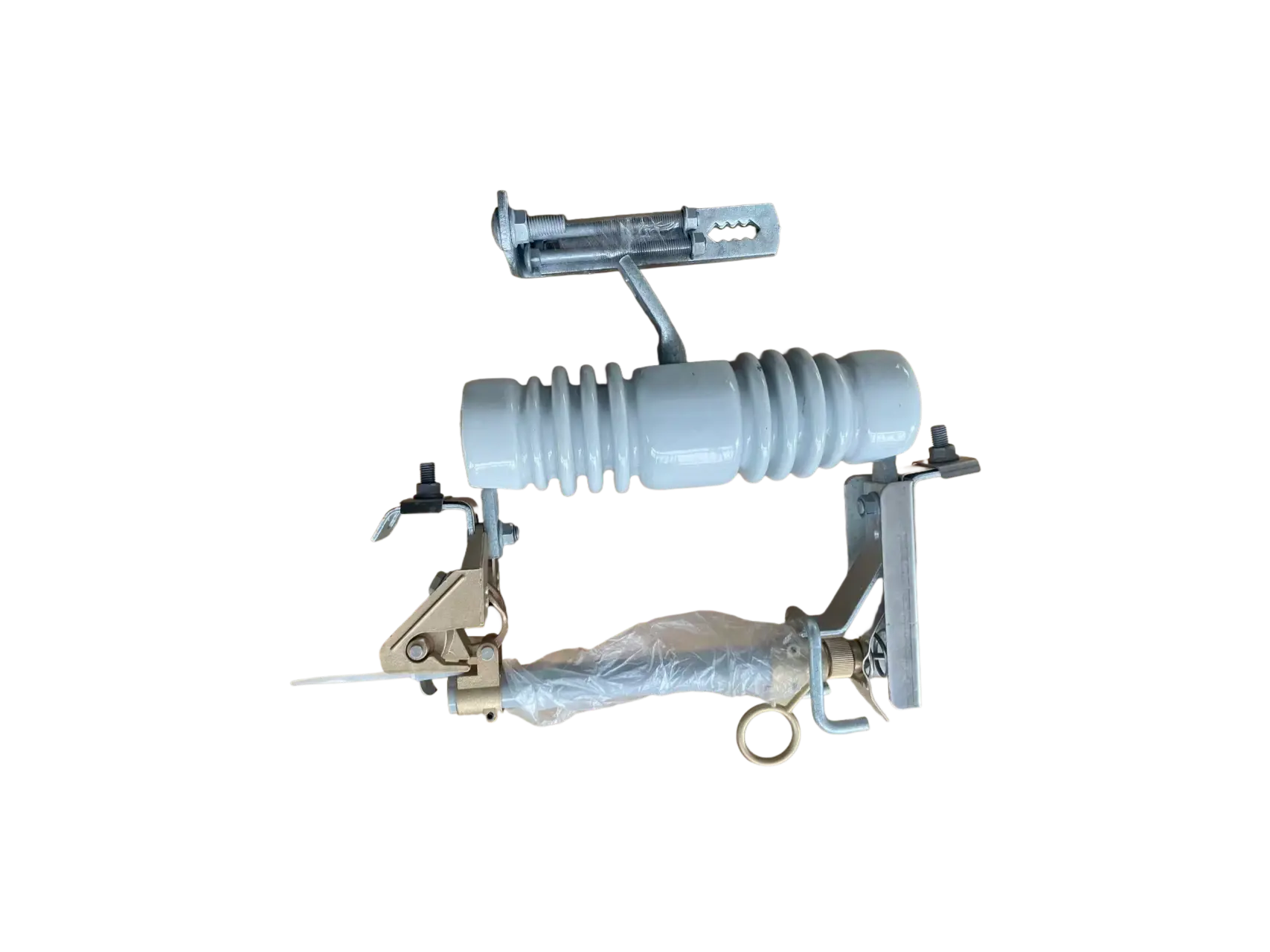

11KV Drop-out fuse cutouts:Outdoor HV Circuit Breaker

Drop-out fuse cutouts and load-break fuse cutouts are outdoor high-voltage protection devices. They are installed on the high-voltage side of distribution transformers or along branch lines of distribution networks. Their primary functions include protecting against short circuits and overloads, as well as distributing load currents among transformers and lines

Ambient temperature range: -30°C ≤ T ≤ +40°C

Maximum operational altitude: ≤ 1000 m

Power frequency specification: 50 Hz ± 2 Hz

Seismic resistance capability: ≤ 7 magnitude on Richter scale

Design wind speed tolerance: ≤ 34 m/s (122.4 km/h)

A drop-out fuse cutout consists of two main components: an insulation support and a fuse tube. Static contacts are located at both ends of the insulation support, while moving contacts are situated at both ends of the fuse tube. The fuse tube itself is composed of an inner arc-extinguishing tube and an outer epoxy glass tube.

The load break drop-out fuse cutout is equipped with elastic auxiliary contacts and an arc-extinguishing chamber to switch load currents .

During normal operation of the drop-out fuse cutout, the fuse tube maintains a closed position through tensile force applied by the fuse link. Upon system failure, fault current induces thermal rupture of the fuse link, resulting in arc formation.

The arc-extinguishing tube, when subjected to arc heating, decomposes to release a significant volume of gas, generating extremely high internal pressure within the tube. This pressurized gas propagates longitudinally through the fuse tube, achieving rapid arc elongation and subsequent extinction. Following fuse link rupture, the inferior movable contact assembly loses structural integrity and detaches from the tension mechanism, enabling gravitational descent of the fuse component to establish a visible isolation gap.

When operating a load-break drop-out fuse cutout, the auxiliary moving and stationary contacts remain engaged during the initial actuation of the main contacts via an insulating operating rod. Continued pulling of the rod subsequently separates the auxiliary contacts, generating an arc between them. The arc is elongated within the narrow slots of the arc-extinguishing chamber, while the chamber generates gases to quench the arc at current zero crossing.

Claire

Claire Mr.Fu

Mr.Fu

Claire

Claire