In the realm of electrical distribution, the RMU Circuit Breaker plays an essential role in ensuring reliability and safety. Designed to manage and protect the electrical circuits within a network, these innovative devices are pivotal in modern energy management systems. As technology advances and the demand for efficient power distribution increases, understanding the key features of RMU Circuit Breakers becomes crucial for engineers and project managers alike.

This article aims to highlight the top ten features of RMU Circuit Breakers that are vital for your projects. By delving into aspects such as operational efficiency, ease of maintenance, and safety mechanisms, we will underscore how these attributes contribute to the overall performance of electrical systems. Whether you are involved in designing, installing, or maintaining electrical infrastructures, being well-acquainted with the features of RMU Circuit Breakers is fundamental. With these insights, you can make informed decisions and ensure that your projects meet both operational excellence and safety standards.

The integration of Ring Main Unit (RMU) circuit breakers into electrical distribution systems has become increasingly essential for ensuring reliability and safety in power management projects. One of the standout features of RMU circuit breakers is their compact design. According to a report by the International Electrotechnical Commission (IEC), RMUs require significantly less installation space compared to traditional setups, making them ideal for urban environments where space constraints are a major consideration.

Another crucial feature is the enhanced safety mechanisms that RMU circuit breakers offer. These units are typically designed with integrated protection against overcurrent and short-circuit conditions, which can prevent damage to both the equipment and the surrounding environment. The Global Industry analytics report indicates that effective circuit protection can reduce outage times by up to 40%, leading to improved operational efficiency and cost savings for businesses. Additionally, their modular architecture allows for easy maintenance and upgrades, ensuring that power systems remain adaptable to emerging technologies and standards. As such, understanding these features can facilitate better decision-making when selecting RMUs for upcoming projects.

| Feature | Description | Benefits |

|---|---|---|

| Compact Design | Space-saving design suitable for limited spaces. | Allows for optimal space utilization in substations. |

| Integrated Protection | Built-in protection relays for overcurrent and earth faults. | Enhances safety and prevents equipment damage. |

| Manual Operation | Easy manual operation for maintenance and testing. | Facilitates quick troubleshooting and system checks. |

| Remote Monitoring | Capable of real-time remote monitoring via communication protocols. | Improves efficiency and reduces downtime with constant status checks. |

| Vibration Resistance | Designed to withstand vibrations in harsh environments. | Increases reliability in industrial settings. |

| Temperature Rating | Operates efficiently across a wide temperature range. | Suitable for various climates and environments. |

| Interlock Mechanism | Safety interlock systems to prevent accidental operation. | Enhances operator safety during maintenance. |

| Modular Design | Modular components for easy upgrades and replacements. | Reduces costs and time for future expansions. |

| Environmental Protection | Designed to meet environmental regulations. | Promotes sustainability in operations. |

| Ease of Installation | Simplified installation process with user-friendly design. | Saves time and reduces labor costs during setup. |

RMU circuit breakers, or Ring Main Unit circuit breakers, are essential components in modern electrical distribution networks. They play a critical role in ensuring the reliability and safety of power supply systems, particularly in medium voltage applications. The primary functionality of an RMU circuit breaker is to provide protection against short circuits and overcurrent conditions, thus preventing potential damage to the electrical infrastructure. They achieve this through their automatic tripping mechanism, which isolates faulty circuits and maintains service continuity for unaffected areas.

Moreover, RMU circuit breakers are designed for compactness and ease of installation, making them suitable for urban settings where space is limited. Their modular design allows for flexible configurations which can be tailored to meet specific project requirements. RMUs not only facilitate the distribution of electricity but also allow for easy maintenance and upgrades without significant downtime.

This adaptability enhances operational efficiency and promotes a sustainable energy framework, making RMU circuit breakers a crucial consideration in electrical engineering projects.

Insulation resistance ratings are critical parameters for any RMU (Ring Main Unit) circuit breaker, playing a vital role in enhancing safety within electrical systems. These ratings essentially measure the resistance offered by insulating materials to the passage of electrical current, which is crucial in preventing accidental short circuits and electrical leaks. According to the International Electrotechnical Commission (IEC) standards, a high insulation resistance, typically exceeding 1,000 megaohms, is often recommended for reliable operation, ensuring that the circuit breakers can withstand electrical stresses without causing failures that could lead to system outages or safety hazards.

Moreover, proper insulation resistance not only affects safety but also impacts the longevity and performance of the RMU circuit breaker. Studies by the Institute of Electrical and Electronics Engineers (IEEE) indicate that maintaining insulation resistance within certain parameters can significantly reduce maintenance costs and improve system reliability. For instance, circuit breakers with poor insulation may exhibit a tendency to degrade faster, requiring more frequent replacements and leading to costly downtimes. Therefore, understanding and selecting RMU circuit breakers with robust insulation resistance ratings can lead to improved safety metrics and operational efficiencies in various electrical projects. This focus on safety and reliability underlines the necessity for thorough evaluation of insulation properties when planning electrical infrastructures.

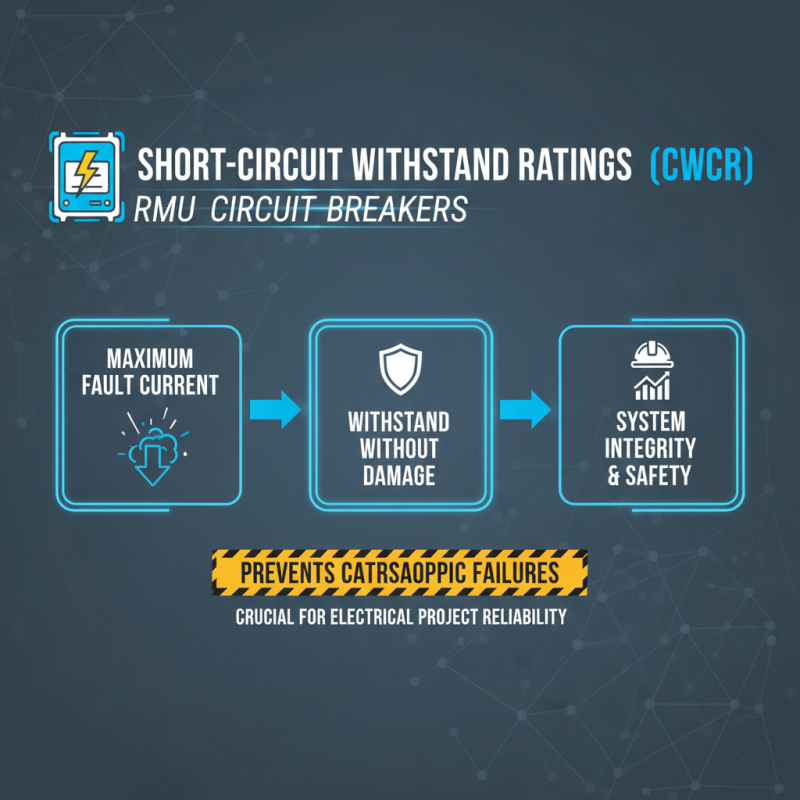

Short-circuit withstand ratings (CWCR) are crucial when selecting RMU (Ring Main Unit) circuit breakers for any electrical project. These ratings indicate the maximum fault current that a circuit breaker can withstand without sustaining damage, ensuring the system's integrity during short-circuit conditions. Understanding CWCR is essential for engineers and designers as it directly impacts the safety and reliability of the electrical distribution system. A circuit breaker with an adequate short-circuit withstand rating can prevent catastrophic failures and protect both equipment and personnel from potential hazards.

Moreover, the importance of short-circuit withstand ratings extends beyond mere compliance with safety standards. They play a vital role in system design and reliability. When an electrical fault occurs, the breaking capability of the RMU circuit breaker must exceed the fault current, allowing it to effectively isolate the affected section of the network. This capability not only safeguards the breaker itself but also minimizes the risk of collateral damage to connected devices and enhances the overall efficiency of the electrical system. Properly evaluating and selecting RMU circuit breakers based on their short-circuit withstand ratings can be a critical factor in the success of a project, ensuring smooth operation and long-term performance.

When considering the integration of RMU circuit breakers in your projects, one of the standout features worth highlighting is their automation compatibility. In today’s rapidly advancing technological landscape, the ability to seamlessly integrate smart technologies into electrical systems is crucial. Automation facilitates efficient monitoring, control, and management of power distribution and enhances reliability by reducing the potential for human error.

For project managers and engineers, understanding and utilizing automation alongside RMU circuit breakers can lead to significant benefits. These breakers often support advanced communication protocols, allowing for real-time data exchange between devices. This capability not only enables remote operation and diagnostics but also supports predictive maintenance, helping to avoid unexpected downtime and extending the lifecycle of equipment.

Tips for leveraging automation compatibility include ensuring proper training for personnel on new technologies and investing in user-friendly monitoring dashboards. Additionally, consider establishing a phased approach to integrating smart technologies, allowing for a smooth transition while assessing performance and making necessary adjustments along the way. This strategic adoption of automation can ultimately result in enhanced operational efficiency and greater system resilience.

: The primary function of RMU circuit breakers is to provide protection against short circuits and overcurrent conditions, preventing potential damage to electrical infrastructure by isolating faulty circuits.

Insulation resistance ratings are important as they measure the resistance of insulating materials, which helps prevent accidental short circuits and electrical leaks, enhancing safety and reliability in electrical systems.

It is recommended that RMU circuit breakers maintain insulation resistance levels exceeding 1,000 megaohms for reliable operation.

Effective maintenance strategies can extend the lifespan of RMU circuit breakers by up to 30%, reducing the likelihood of unexpected failures and improving reliability.

Lifecycle management involves the complete journey of circuit breakers from installation to decommissioning, including regular inspections, upgrades, and timely replacements to optimize performance and reduce ownership costs.

A well-executed lifecycle management plan can reduce total ownership costs by up to 20% over the lifespan of a circuit breaker, making it crucial for cost-effectiveness in electrical systems.

RMU circuit breakers are designed for compactness and ease of installation, making them suitable for urban settings where space is limited, while also allowing for easy maintenance and upgrades.

Their modular design allows for flexible configurations, and their adaptability promotes efficient operation and reduces downtime during maintenance or upgrades.

RMU circuit breakers facilitate the distribution of electricity safely and reliably, which supports the development of a sustainable energy framework in electrical engineering projects.

The article "Top 10 Rmu Circuit Breaker Features You Should Know For Your Projects" provides a comprehensive overview of essential characteristics that make RMU circuit breakers vital for modern electrical projects. It begins with an understanding of their key functionalities and applications before delving into specific features that enhance safety and efficiency.

Key features include high insulation resistance ratings for improved safety, and short-circuit withstand ratings which are crucial for preventing system failures. The article also emphasizes the importance of automation compatibility, allowing for the integration of smart technologies into power systems. Additionally, it discusses environmental considerations such as IP ratings, which ensure performance in various conditions, and highlights the significance of maintenance requirements for effective lifecycle management of RMU circuit breakers. This knowledge is invaluable for any engineering project aiming to prioritize safety and operational efficiency.