In the electrical industry, a "Molded Breaker" plays a crucial role in circuit protection. According to the latest Market Research Report, the global molded case circuit breaker market is expected to grow significantly, reaching USD 4.5 billion by 2025. This growth is driven by rising demand for energy-efficient solutions and increased safety measures.

John Smith, a leading expert in electrical engineering, emphasizes, “Molded Breakers are essential for modern electrical systems.” This statement highlights their importance in preventing overloads and short circuits. They work by automatically interrupting the flow of electricity when faults occur.

Despite their advantages, there are challenges in using molded breakers. Some users may overlook regular maintenance and testing. It’s vital to understand that neglect can lead to failures at critical moments. As organizations adapt to evolving standards and technologies, the need for proper education about molded breakers cannot be overstated.

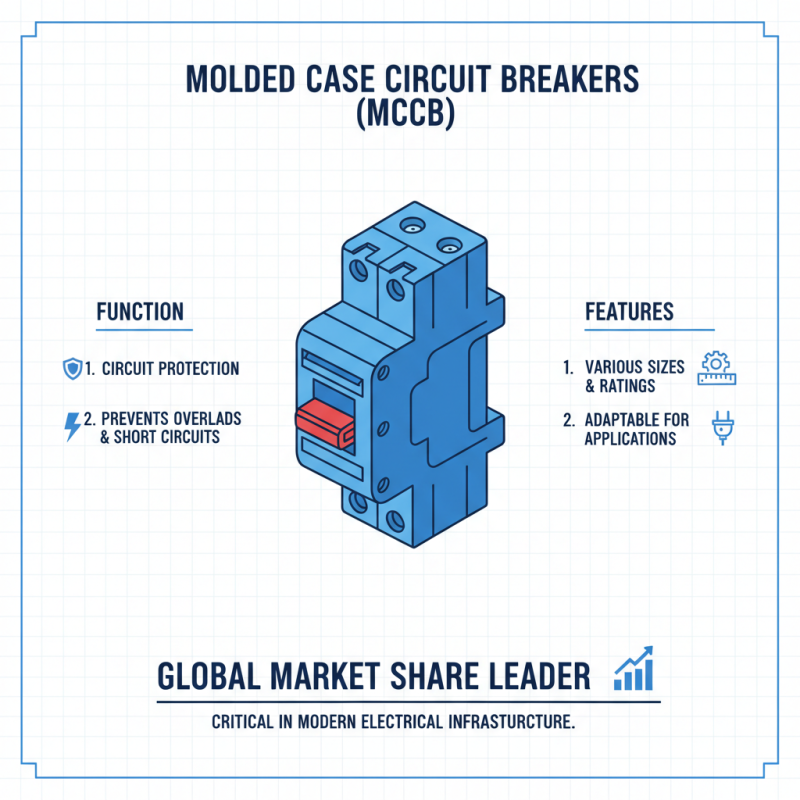

A molded breaker is an essential component in electrical systems. It is designed to protect circuits from overloads and short circuits. These breakers come in various sizes and ratings, tailored for different applications. According to industry reports, molded circuit breakers accounted for a significant percentage of the global market share, reflecting their importance in modern electrical infrastructure.

The mechanism of a molded breaker relies on an electromechanical component. When excessive current flows, it trips the circuit, stopping the current. This helps prevent equipment damage and enhances safety. The compact design of molded breakers allows for efficient use of space in electrical panels. In many installations, maintaining proper thermal limits is crucial for optimal performance.

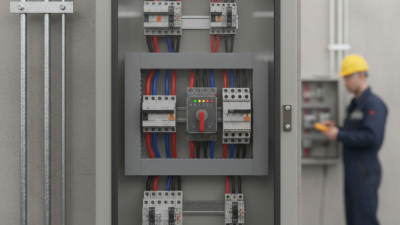

Tips for installation: Ensure correct sizing based on load requirements. It's critical to select the right rating for the intended use. Regular inspections can prevent malfunction due to wear or environmental factors. For those uncertain about installation, consulting with a professional can prevent costly mistakes. Balancing theoretical knowledge with practical experience is vital. Mistakes can lead to dangerous situations. Always prioritize safety in any electrical project.

Molded breakers are essential components in electrical systems. Understanding their building blocks helps us appreciate their function. Each molded breaker consists of several key parts, such as the frame, contacts, terminals, and trip mechanisms.

The frame houses the internal components. It provides structural support and insulation. Contacts enable the flow of electricity. They open and close to interrupt the circuit when needed. Terminals connect the breaker to the electrical supply. The trip mechanism is vital for safety. It detects overloads and short circuits, preventing damage.

Tips: When working with molded breakers, always ensure they are rated properly for your application. This avoids potential hazards. Check the connections regularly. Loose terminals can lead to overheating. Lastly, consider the environment where the breaker operates. Dust and moisture can affect performance.

Sometimes, mistakes happen. A breaker could trip unexpectedly, leaving devices vulnerable. Reflect on these moments and learn. Proper installation is crucial, but it only takes one oversight to create a problem. Understanding how each component works will make troubleshooting easier.

Molded breakers play a crucial role in electrical systems. They are designed to protect circuits from overloads and short circuits. When excessive current flows, the breaker trips, stopping the flow of electricity. This mechanism prevents damage to devices and minimizes fire hazards.

In operation, molded breakers use a bimetallic strip, a moving contact, and an electromagnetic mechanism. When current exceeds safe levels, the bimetallic strip bends. This bending trips the switch to open the circuit. It's a reliable way to ensure safety in homes and industries. However, not all breakers respond the same way. Some may trip too late. Regular checks are essential for optimal performance.

Tips: Always choose the right size breaker for your circuit. A breaker that is too small can trip frequently. Conversely, one that is too large may not trip when it should. Check regularly for wear and ensure connections are tight. This maintenance can extend the life of your electrical system.

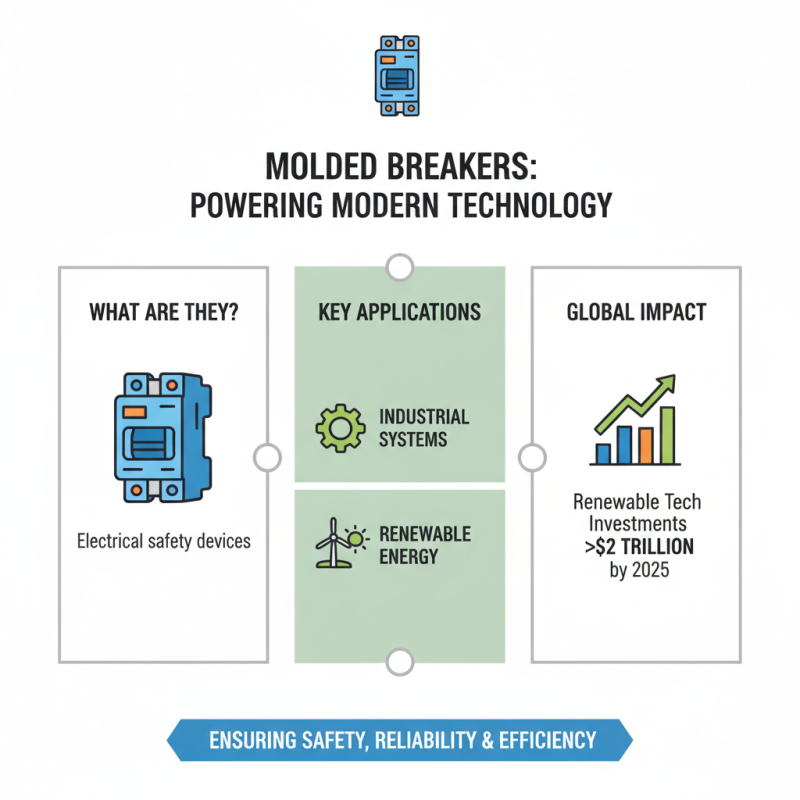

Molded breakers are vital components in modern technology. They are used in various sectors, ensuring safety and reliability. One significant application is in renewable energy systems. According to industry reports, global investments in renewable technologies are expected to exceed $2 trillion by 2025. Molded breakers protect these systems from overload and short circuits. This enhances their efficiency and longevity.

In industrial settings, molded breakers play a crucial role in machinery. Studies highlight that improper protection can lead to machinery downtime, costing companies up to $1 million per hour. Molded breakers mitigate these risks. Moreover, their integration with smart technologies is on the rise. This trend allows for real-time monitoring, improving operational efficiency.

However, the adoption of molded breakers is not without challenges. Some environments may pose risks of misapplication. Engineers must choose the right specifications carefully. Overlooking small details can lead to failures. The need for thorough testing and validation remains paramount in these applications. This aspect is often neglected, leading to safety concerns and economic losses.

Molded breakers play a crucial role in electrical safety. Their design includes features that protect against overloads and short circuits. These breakers detect when too much current flows and automatically shut off the power. This prevents fires and equipment damage, ensuring safety in homes and businesses.

One key safety feature is the Ground Fault Circuit Interrupter (GFCI). It quickly cuts off power when it senses discrepancies between incoming and outgoing current. This protects against electric shocks, especially in wet areas. An additional feature is the Arc Fault Circuit Interrupter (AFCI), which identifies arc faults that can lead to electrical fires. Both of these features significantly enhance safety.

It's essential to regularly test these breakers to ensure they function correctly. Many users forget this simple step. If a breaker trips frequently, it may indicate an underlying problem. Reflecting on the maintenance of molded breakers can prevent dangerous situations. Their safety features are vital, but only if they are properly monitored and maintained.