Choosing the right Vacuum Ckt Breaker (VCB) is crucial for ensuring electrical safety and efficiency. According to a recent industry report by MarketsandMarkets, the global circuit breaker market is expected to reach $13.4 billion by 2025. This growth underscores the increasing importance of selecting appropriate electrical components. A VCB is an integral part of this market, known for its effectiveness in medium-voltage applications.

VCBs operate by isolating electrical circuits during faults, thus preventing damage. Their reliability is highlighted in studies showing that proper selection can reduce system failures by up to 30%. However, many users still overlook factors such as switching capacity and environmental conditions when making their choices. This often leads to inadequate protection and increased operational risks.

As the demand for energy-efficient solutions rises, selecting a VCB tailored to specific needs becomes more vital. A mismatch can cause catastrophic failures and downtime. Therefore, understanding the operational requirements and potential challenges is essential. The right VCB can offer significant long-term benefits, but it requires careful consideration and knowledge of its functionalities.

Understanding Vacuum Circuit Breakers: Definition and Functionality

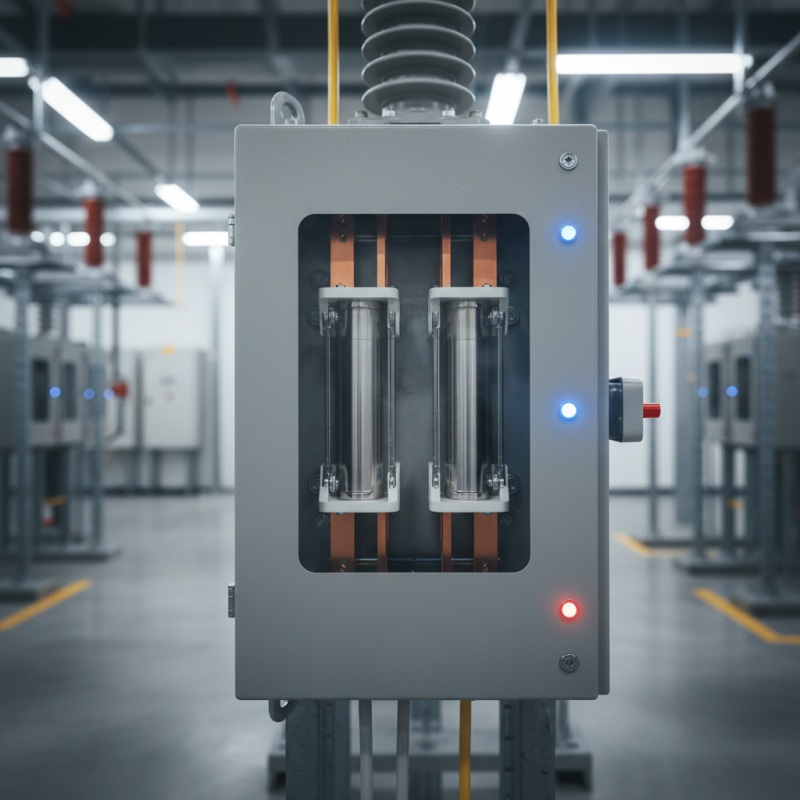

Vacuum circuit breakers (VCBs) are crucial for modern electrical systems. They operate by extinguishing the arc in a vacuum chamber. When current flows, the contacts separate. This creates an electrical arc. The vacuum quickly cools and quenches the arc. This process prevents damage to the circuit.

VCBs offer several benefits.

They are compact and ideal for indoor installations. Their maintenance is easy, often requiring less frequent checks. However, they are not suitable for all applications. The voltage ratings and operational needs must be aligned.

Tips: Always assess your specific requirements before selecting a VCB. Check the voltage and current ratings closely. Consider the layout of your electrical system. Evaluate the space available for installation.

Another point to consider is the environmental conditions. VCBs perform best in controlled environments. Excessive dust or humidity can affect their functionality. Regular inspections help ensure a long service life, but these can be overlooked.

An understanding of these factors can prevent mistakes in choosing a vacuum circuit breaker. Make informed choices for better reliability.

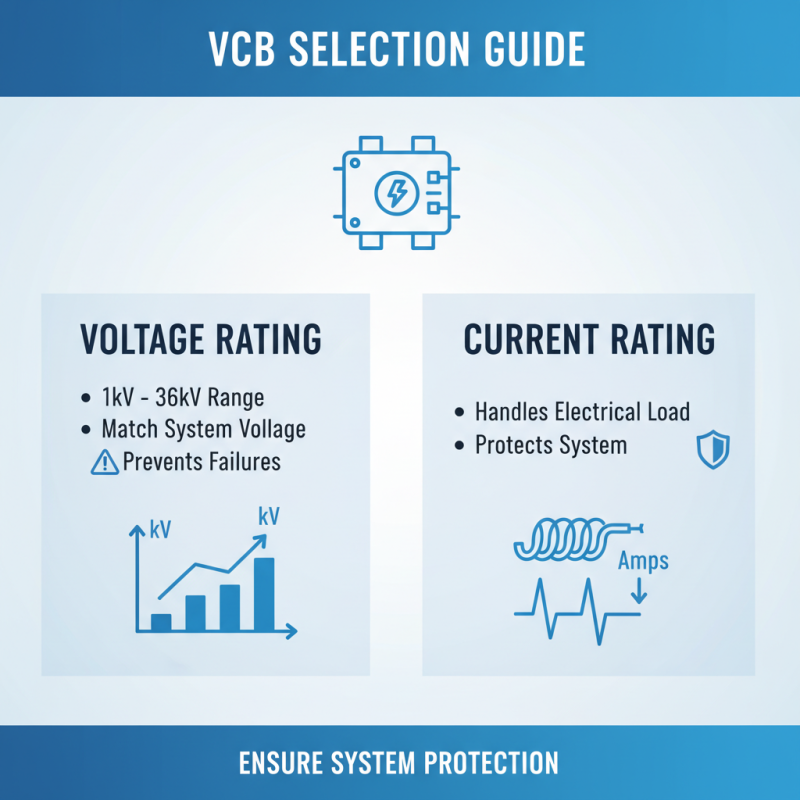

When selecting a vacuum circuit breaker (VCB), understanding the voltage and current ratings is crucial. These specifications ensure that the VCB can handle the electrical load and protect your system. Common voltage ratings for VCBs range from 1kV to 36kV. It's essential to match the VCB to your system voltage to prevent failures.

Current ratings typically depend on the application. VCBs can have ratings from 630A to 4000A and should align with the maximum load of your electrical system. According to the Institute of Electrical and Electronics Engineers (IEEE) standards, selecting a VCB with a current rating about 20% higher than your peak load is advisable. This buffer helps accommodate unexpected surges.

**Tip:** Always consult the latest technical data sheets when choosing a VCB. This ensures you have accurate ratings aligned with current standards.

Consider the environmental factors too. VCBs may perform differently in extreme temperatures or humidity. The protective measures for dirt and dust can impact their lifespan. A common oversight is ignoring these conditions during selection.

**Tip:** Evaluate your installation environment carefully. It will influence the VCB's efficiency and reliability over time.

When choosing a vacuum circuit breaker, environmental conditions play a significant role. Temperature and humidity affect its performance. High temperatures can lead to overheating. This can cause insulation failure if not monitored. On the other hand, excessive humidity can create condensation. Moisture in electrical components is a risk. It may lead to corrosion and malfunction.

Tips: Always check local climate conditions. Use breakers designed for specific temperatures. Ensure proper ventilation in your electrical rooms to reduce humidity.

Consider other environmental factors too. Dust and pollutants can impact the circuit breaker’s efficiency. In industrial settings, contaminants may accumulate. This requires more frequent maintenance checks. What about extreme weather? That can also impact functionality.

Understand your unique situation. The wrong choice can lead to failures. Think about the long-term effects on your electrical system. Balancing performance with environmental conditions is crucial.

When selecting a vacuum circuit breaker (VCB), understanding safety standards is crucial. IEEE and IEC ratings govern how these devices perform under various conditions. Compliance ensures that the equipment can handle short circuits and overloads effectively. According to the IEEE 242-2001, VCBs should be capable of interrupting fault currents. This is essential for systems that require high reliability. The right ratings can prevent significant damage during electrical failures.

Safety ratings also impact maintenance practices. Proper adherence to IEC 60255 can enhance lifespan and operational safety. Devices that meet these standards often have better insulation and protection mechanisms. Reports indicate that equipment failing to comply with these criteria can lead to inefficiencies. A study from the International Electrical Testing Association found that non-compliant devices had a 25% higher failure rate.

Choosing the right VCB isn’t just about functionality. It’s also about ensuring peace of mind. Many projects suffer setbacks due to compliance oversights. This can be costly and time-consuming. Some installers still overlook critical ratings, exposing them to risks. Therefore, careful consideration of IEEE and IEC standards is not optional. It's a fundamental aspect of responsible electrical engineering.

| Dimension | Description | Standard | Importance |

|---|---|---|---|

| Voltage Rating | The maximum voltage the breaker can handle. | IEEE C37.20.1 | Ensures safety and reliability in operation. |

| Current Rating | The rated continuous current the circuit breaker can carry. | IEC 60947-2 | Critical for selecting the right breaker for load. |

| Breaking Capacity | The highest fault current the breaker can safely interrupt. | IEEE C37.013 | Prevents damage to equipment during faults. |

| Type of Protection | Different types include electromagnetic, thermal, or electronic. | IEC 60947-2 | Determines how the breaker reacts to overloads. |

| Environmental Ratings | Protection against dust, moisture, and other environmental conditions. | IEC 60529 | Ensures long-term functionality in various conditions. |

When selecting the right vacuum circuit breaker (VCB), balancing cost and performance is crucial. According to a recent industry report, over 30% of users experienced financial strain due to inadequate upfront investment in VCBs, leading to higher long-term maintenance costs. A high-quality VCB can significantly reduce downtime and enhance system reliability. This initial cost might appear steep, but it paves the way for long-term savings.

**Tip:** Compare models based on their lifecycle cost, not just their purchase price. Investing in a reliable VCB can save future headaches.

Another essential aspect is performance metrics. Many VCBs have a capacity rating that determines their efficiency and durability. Reports indicate that models with higher ratings may be more cost-effective in the long run, even if they require a larger initial investment. Yet, evaluating the specific power requirements of your system is often overlooked. Not all high-performance models are necessarily suitable for every setting.

**Tip:** Consider the specific electrical demands of your facility before making a decision. Unexpected power surges can lead to failures, affecting productivity.

Ultimately, the choice of a VCB must reflect both current and future electrical needs. While cost is a significant factor, prioritizing performance could lead to substantial benefits. Careful consideration allows for a decision that may seem flawed initially but will prove sound over time.