In the dynamic world of electrical systems, choosing the right components is critical. Molded breakers, essential for circuit protection, are often overlooked. These devices prevent overload and short circuits in residential and industrial settings. According to a recent industry report by Research and Markets, the global molded case circuit breaker market is projected to grow at a CAGR of 6.2% from 2021 to 2026. This highlights their increasing significance.

Expert John Smith, a leading figure in the electrical engineering field, emphasizes, “Reliable protection begins with the proper selection of molded breakers.” His insight reflects a common industry consensus on the necessity of using quality molded breakers for effective circuit management. With various types available, such as thermal-magnetic and electronic molded breakers, each type offers unique benefits tailored to specific applications.

However, even within a growing market, not all options are created equal. Some may lack the necessary certifications or have inconsistent performance metrics. Evaluating these factors requires diligence. Ultimately, understanding the diversity of molded breaker types is crucial for meeting specific electrical needs while maintaining safety and efficiency.

Molded circuit breakers are essential in modern electrical systems. They protect circuits from overloads and short circuits. Understanding how they work can help you choose the right type for your needs. These breakers come in different styles, each catering to specific applications.

They are designed with thermal and magnetic elements. The thermal part reacts to heat, while the magnetic part responds to sudden surges. This dual protection mechanism is crucial for safety. However, choosing the wrong type may lead to frequent trips. It can also result in inadequate protection, which is dangerous.

Installation can be tricky. Proper sizing and placement are necessary for optimal performance. Many people overlook the importance of these factors. When in doubt, consulting with a professional can help. Paying attention to details can prevent future issues. Choosing the right molded breaker is not as simple as it seems.

This chart illustrates the usage frequency of different types of molded breakers used in electrical systems. Miniature Circuit Breakers are predominantly used, followed by Residual Current Circuit Breakers, Air Circuit Breakers, and Molded Case Circuit Breakers.

Molded circuit breakers (MCBs) are essential for modern electrical systems. There are various types to consider based on your unique needs. Two common types are the thermal magnetic breaker and the electronic breaker. The choice often depends on the specific application and required features.

Thermal magnetic breakers rely on heat and magnetism to trip. They provide reliable overload and short-circuit protection. Electronic breakers, however, offer precise trip settings. According to industry reports, electronic breakers are increasingly popular in commercial settings. They allow better monitoring of energy usage and sensitive equipment protection.

Tips: When selecting an MCB, consider the load types in your system. For a home environment, standard thermal magnetic breakers are usually adequate. In contrast, commercial installations often benefit from electronic models for enhanced safety features.

Also, the National Electrical Manufacturer Association (NEMA) suggests assessing environmental factors. High humidity or dust can impact MCB performance. Not every breaker suits every environment. Always touch base with an electrician for tailored advice. Remember that choosing an MCB is not just about the price. It’s about safety and protecting your investment.

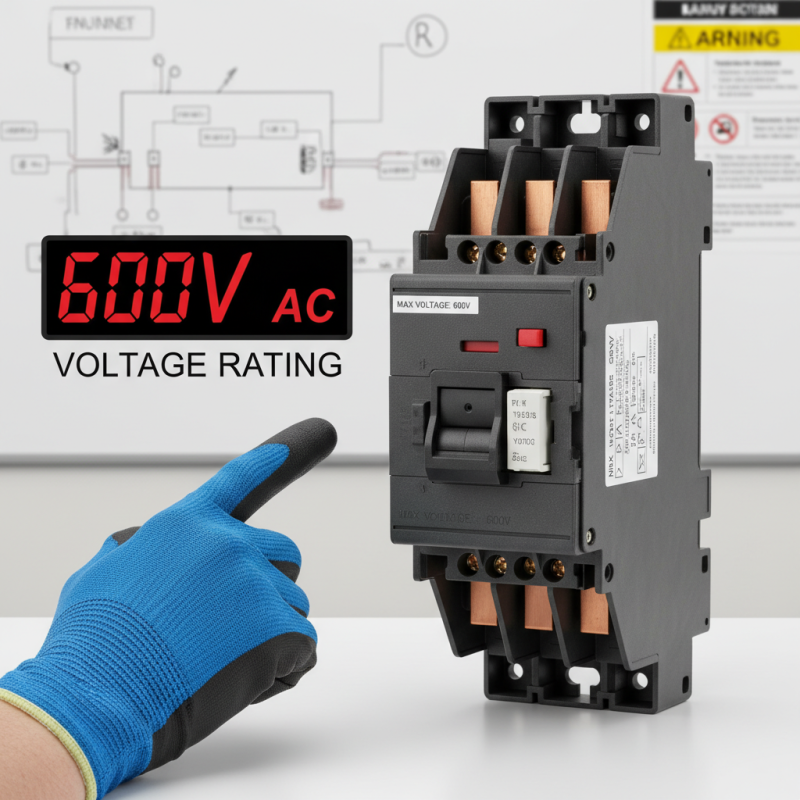

When choosing molded circuit breakers, several key features should be considered. Firstly, the voltage rating is crucial. It determines the maximum voltage the breaker can handle. Incorrect ratings can lead to equipment failure or fire hazards. Look for breakers compatible with your electrical system's voltage levels.

In addition, consider the current rating. This indicates how much load the breaker can manage. Selecting a breaker with too low a current rating can trip frequently. On the other hand, an oversized breaker might not protect your system adequately. Check if the breaker has features like overload and short circuit protection. These add layers of safety.

The physical size and mounting options of the breaker matter too. Make sure it fits into your existing panel. If your panel space is limited, you may need a compact breaker. Also, reflect on thermal and magnetic tripping characteristics. Each application may require different settings. Proper evaluation of these factors ensures optimal performance and safety.

When comparing molded breakers to other circuit protection devices, several factors surface. Molded circuit breakers are known for their reliability. They provide both overcurrent protection and switching capabilities. Unlike fuses, once a molded breaker trips, it can be easily reset. This eliminates the need for constant replacements. In contrast, fuses must be replaced after a single use. That can make molded breakers more economical over time.

However, molded breakers can be larger and more expensive upfront. Other devices, like miniature circuit breakers (MCBs), can offer a cheaper alternative for smaller applications. MCBs are compact and effective for residential use but may not handle large industrial loads. Users often face a dilemma: balance initial investment with performance capacity.

Moreover, the choice often depends on specific electrical requirements. Some applications may only need simple overcurrent protection. In these cases, fuses might suffice. Still, the added functions of molded breakers can provide necessary peace of mind. Choosing the right device is not always clear-cut. It requires thorough evaluations and sometimes tough decisions.

| Breaker Type | Current Rating (A) | Voltage Rating (V) | Breaking Capacity (kA) | Tripping Characteristics | Ideal Application |

|---|---|---|---|---|---|

| Molded Case Circuit Breaker (MCCB) | 16 - 630 A | 240/480 V | 10 - 65 kA | Thermal & Magnetic | Industrial motors, transformers |

| Miniature Circuit Breaker (MCB) | 6 - 125 A | 230/400 V | 3 - 10 kA | B, C, D Type | Lighting, small appliances |

| Earth Leakage Circuit Breaker (ELCB) | 16 - 100 A | 230/400 V | 6 - 10 kA | Residual Current | Personal protection, damp areas |

| Dual Function Breaker | 30 - 125 A | 230/400 V | 10 kA | Thermal & Residual Current | Commercial buildings |

| Smart Circuit Breaker | 15 - 100 A | 120/240 V | 10 kA | Integrated Monitoring | Home automation systems |

When installing molded breakers, proper placement is key. Ensure the breakers are easily accessible. This makes future maintenance easier. Use suitable tools for installation. A flathead screwdriver is often essential. Take care to follow all guidelines provided during installation. A small mistake could create issues later.

Maintenance of molded breakers is vital for safety. Check the breakers regularly for signs of wear. Look for loose connections or discoloration. These could indicate potential problems. Keep the area around the breakers clean and dry. Dust and moisture can lead to malfunctions. It's important to periodically test the breakers to ensure they trip correctly.

Remember, mistakes can lead to big issues. If unsure about anything, consulting an expert is wise. Avoiding shortcuts during installation can save time in the long run. Molded breakers are sturdy, but they require attention. Rethink your maintenance routine regularly. A proactive approach is always beneficial.