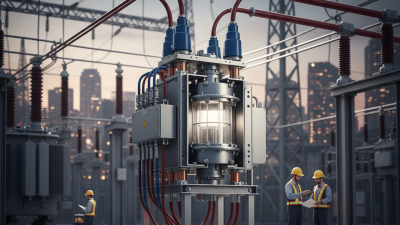

In today's electrical systems, safety and efficiency are paramount. A Vacuum Ckt Breaker (VCB) plays a crucial role in achieving both. Its innovative design allows for superior interruption capabilities. This ensures protection in various settings, from commercial buildings to industrial plants.

The VCB creates a vacuum environment for the arc quenching process. This leads to less maintenance and longer operational life. Users often appreciate its compact size, which saves valuable space in electrical rooms. Many engineers choose VCBs for their reliability, yet not everyone fully understands their advantages.

Despite its benefits, some may overlook the importance of proper installation and regular inspections. A well-installed VCB can prevent costly downtime. However, those who neglect these practices may face unexpected failures. Ultimately, understanding the numerous benefits of a Vacuum Ckt Breaker can lead to better electrical safety and efficiency in various applications.

Vacuum circuit breakers (VCBs) play a crucial role in enhancing electrical safety. They are designed to operate in a vacuum, which significantly reduces the risk of arcing during circuit interruptions. This feature ensures that dangerous electrical faults can be managed effectively, protecting both equipment and personnel. With a lower chance of electrical fires, VCBs provide a safer environment in industrial and commercial settings.

One of the significant benefits of VCBs is their ability to maintain operational efficiency. They provide rapid response to faults, minimizing downtime. Quick and reliable operation is key in modern electrical systems. This efficiency not only preserves equipment but also leads to cost savings. Utility companies and industries benefit greatly from the enhanced reliability of these breakers.

**Tips:** Regular maintenance of vacuum circuit breakers is essential. Check insulation levels and ensure that the vacuum integrity is intact. Consider scheduling periodic inspections to identify potential issues early. Training staff on VCB functions can also reduce human errors and improve safety protocols. Proper education strengthens the entire safety system.

Vacuum circuit breakers (VCBs) play a significant role in enhancing electrical system efficiency. They operate by isolating circuits when faults occur, preventing damage. This mechanism simplifies maintenance tasks and reduces downtime.

VCB technology employs a vacuum environment to quench the arc during operation, ensuring minimal energy loss. This leads to improved energy efficiency, which is crucial in today’s energy-focused landscape.

The benefits of using VCBs extend beyond operational efficiency.

Their compact design allows for easier installation in limited spaces. With fewer mechanical components, these devices reduce the risk of mechanical failures. However, it is essential to ensure that VCBs are well-maintained. Ignoring routine checks can lead to unexpected failures. A proactive approach to maintenance will maximize the advantages of VCB technology, making it even more reliable.

In some situations, users may overlook the significance of proper training when implementing VCBs. Knowledge gaps can lead to mishandling and reduced effectiveness. Regular training sessions can bridge these gaps, ensuring that personnel are well-informed about the technology. By addressing these challenges head-on, organizations can fully leverage the potential of vacuum circuit breakers for electrical safety and efficiency.

Arc flash hazards pose significant risks in electrical systems. These dangers can lead to severe injuries and costly damages. Vacuum circuit breakers (VCBs) mitigate these risks effectively. They contain the arc within the vacuum chamber, allowing for quicker interruption of the fault. This greatly minimizes the chance of an arc flash occurring.

The design of VCBs enhances safety in various environments. They offer quick response times during electrical faults, reducing the duration of exposure to dangerous conditions. This quick action is crucial in maintaining a safer working environment. With the effectiveness of VCBs, companies may find reduced insurance costs and liability risks. However, not all facilities entirely understand how to optimize their use.

Emphasizing training on VCB operation is essential. Staff must comprehend not only how to use this technology but also its limitations. Inadequate training can lead to overconfidence or neglect of safety protocols. Incorporating simulations can deepen understanding and increase preparedness for real-life situations. A more thorough approach to using VCBs leads to improved electrical safety across the board.

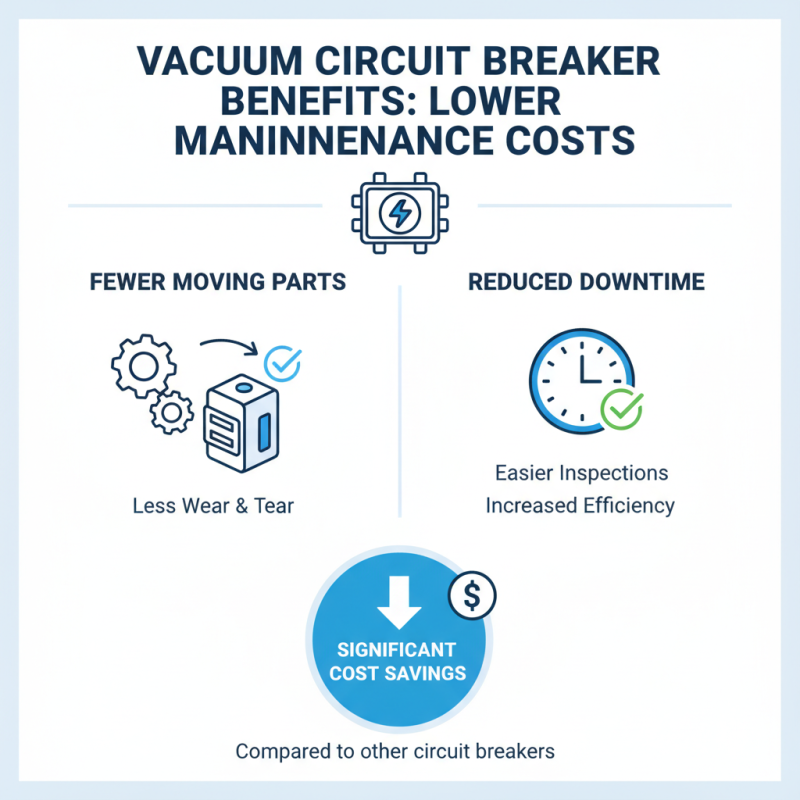

Vacuum circuit breakers (VCBs) offer significant benefits, particularly in maintenance costs. Unlike other circuit breakers, VCBs have fewer moving parts. This simplicity leads to less wear and tear over time. Regular inspections can often be more manageable compared to more complex systems. For facilities aiming for efficiency, lower maintenance translates into reduced downtime.

Additionally, vacuum circuit breakers operate efficiently in various conditions. Their design prevents contact oxidation and contamination. This sustainment helps avoid frequent replacements and repairs. However, not all issues are preventable. Sometimes, operators may overlook minor indicators of wear. Such negligence can result in unexpected breakdowns.

Understanding the specific needs of a facility is crucial. A vacuum circuit breaker may be a step in the right direction, yet it is not a one-size-fits-all solution. Facility managers must ensure thorough training and knowledge-sharing about these systems. Even with its advantages, the effectiveness relies heavily on proper management and awareness of potential pitfalls.

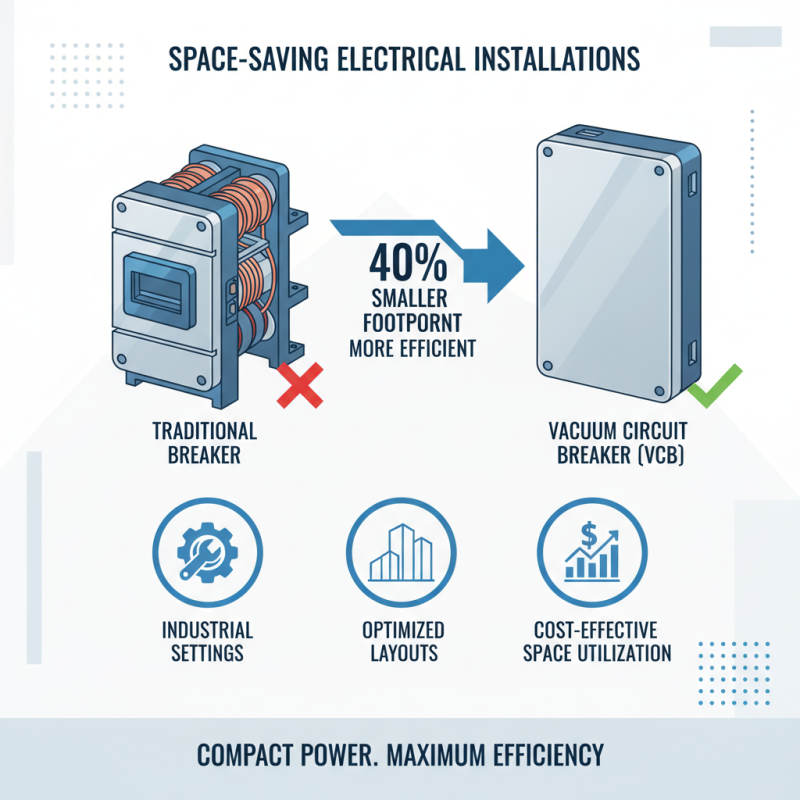

When considering electrical installations, a vacuum circuit breaker (VCB) stands out for its compact design. This feature greatly benefits spaces with limited room. In tight quarters, a VCB takes up less space than traditional circuit breakers. Its small footprint is particularly useful in industrial settings. Less space occupied means more efficient use of valuable real estate. Installing these breakers can lead to optimized layouts that reduce clutter.

A VCB's design brings challenges as well. While compact, maintenance can be tricky due to limited access in confined spaces. Technicians may need special tools or techniques. This is worth reflecting on. A poorly designed layout could lead to costly delays during repairs. Moreover, not all electrical personnel might be trained for these newer systems. Ensuring proper training is essential for maximizing efficiency and safety.

The space-saving aspect also includes installation benefits. A VCB can adapt easily to various environments. It supports modular system designs, which facilitate upgrades. However, rapid advancements may deter organizations from investing in a long-term solution. They might hesitate to adopt new technology, fearing quick obsolescence. Keeping pace with such changes can be overwhelming but is necessary for better energy management.